International Association of Learning Factories

In 2011, the IALF was founded in in Darmstadt, Germany, as an union of several professors running European Learning Factories. In the same year, the international Conference on Learning Factories (CLF) in Darmstadt, took place. Due to the increased internationalization and as the number of members steadily raised to 31, an presidential committee and scientific committee were introduced in 2021 in addition to the presidency. During the yearly held conference, the General Assembly takes place during which among other activities new members and the organization are elected, projects are presented and discussed and news concerning the learning factories of the members are introduced. In working groups, the international members collaborate in research projects and work on joint research papers. We also have several offers for researchers, students and industry.

Our Mission

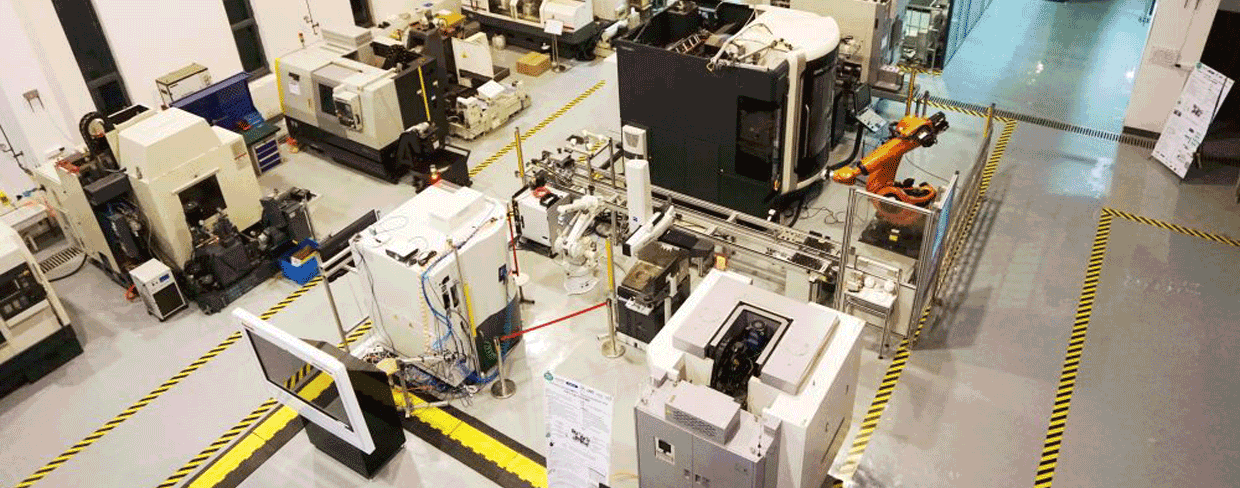

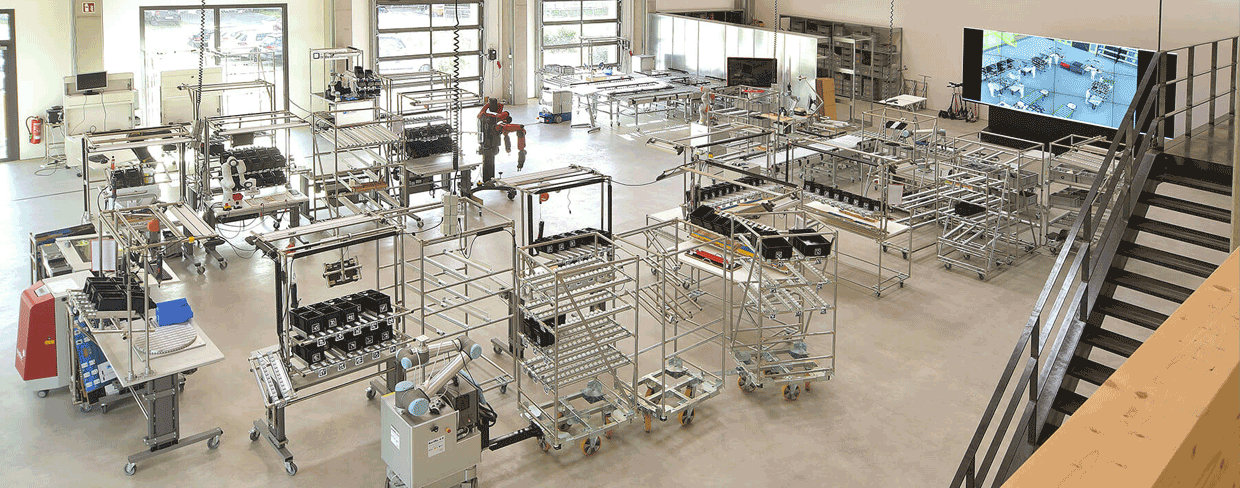

Excellently prepared students, qualified engineers and workers must plan and implement the necessary steps. Qualification processes must be oriented towards these practical requirements. The appropriate learning systems for developing the competences for setting up and operating new production processes are the success factors for the factory of the future.

Our mission is to design learning systems in such a way that stakeholders can grasp the complex technical and organisational interrelationships of today's industrial environment and obtain the competences to systematically improve it. We are convinced that the key to competitiveness more than ever will be

- the enhancement of competencies for technical students and

- efficient training and qualification “on the job in industry” with newest processes and developments

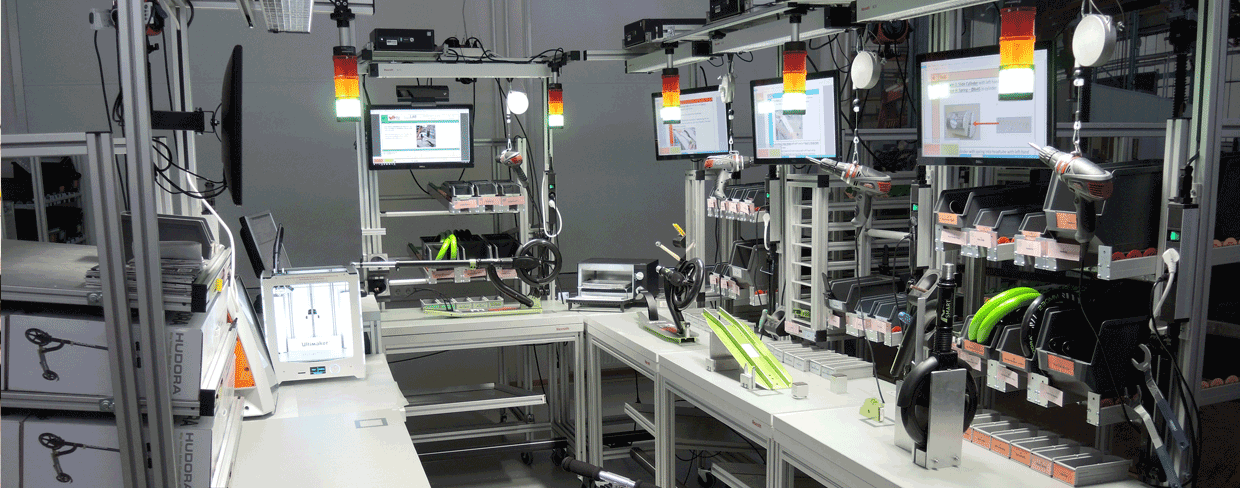

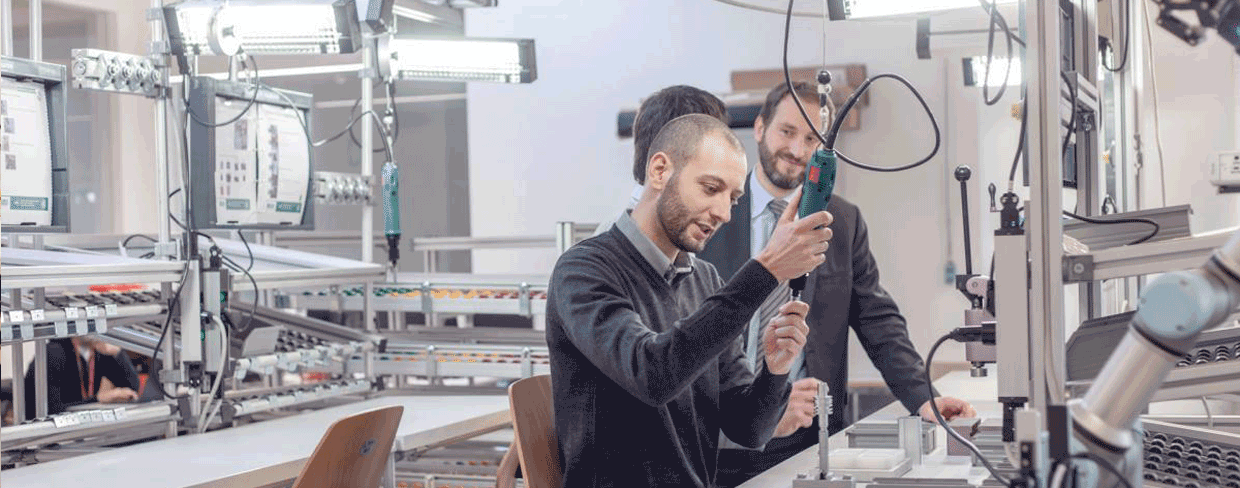

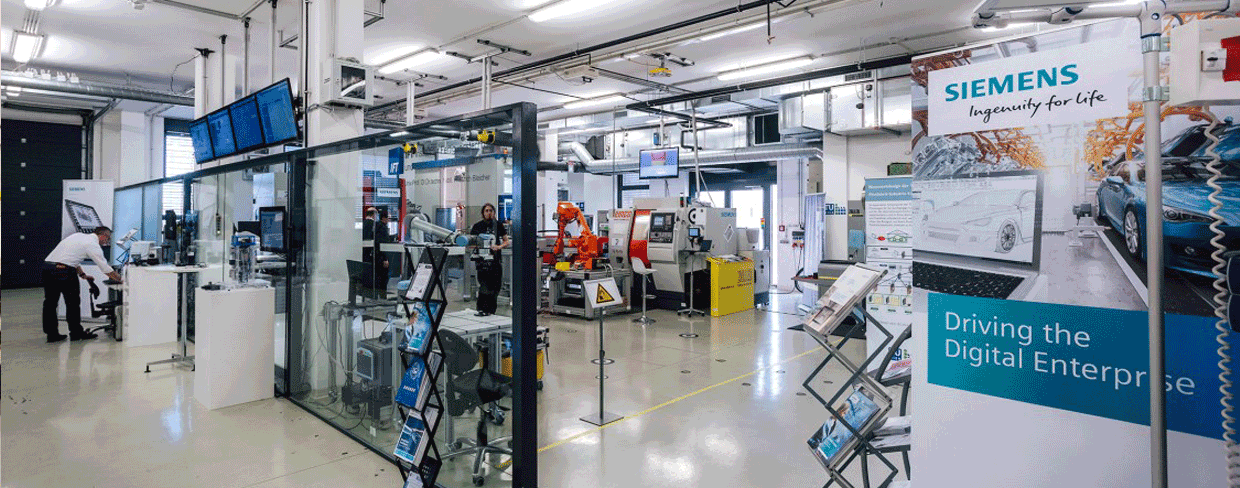

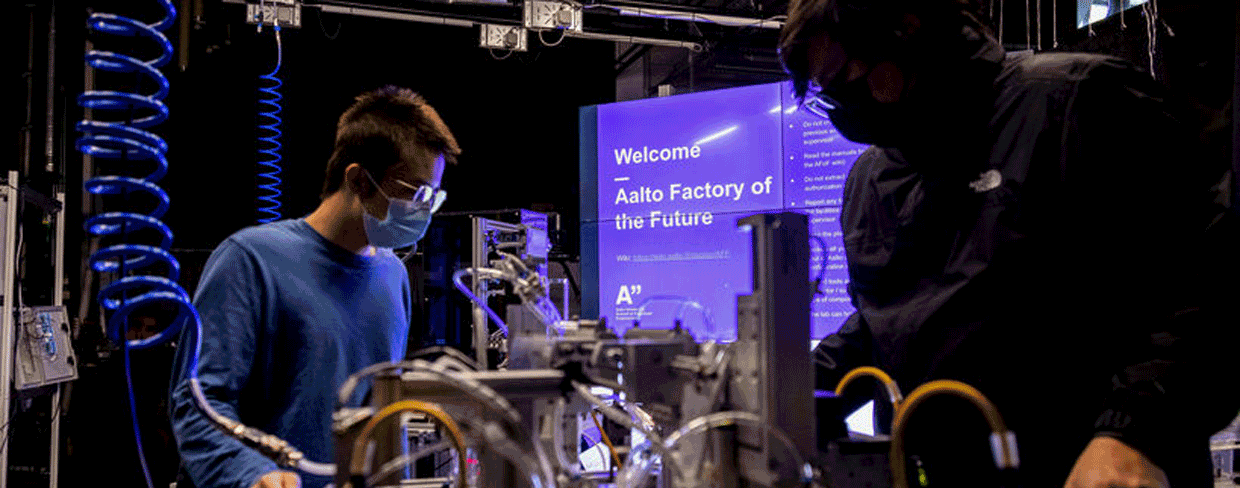

We are a group of research institutions which is driven by the idea that classical forms of class room education in manufacturing, product development and logistics are no longer appropriate. We believe, that lessonsand seminars should be supplemented by learning in a realistic environmentwe call learning factory. Here, course participants can analyse realistic processes for improvement opportunities and deepen experience in the use of methods for continuous improvement. In this way, they are prepared for an industrial or academic career and they gain self-confidence and the enthusiasm to implement new technologies.

We all work on actual challenges for manufacturing and product- developing and integrate newest results into our learning factories and our course programs. Our students and our partners from industrial practice benefit from this. At the same time, we create a link between theory and practice.

This new approach to competency development for industrial production requires comprehensive expertise in the fields of manufacturing technology, production organisation and digitalisation. This ties up extensive resources at our research institutions in terms of both staff and infrastructure. To be successful in the long term, our work must be based on

- exchange of knowledge, modules, solutions in our group

- close cooperation with partners from industry

Only together we can contribute to a successful transforming of our manufacturing industry and our economies!

Our members strive for:

- exchange of knowledge, good practices and learning modules

- built up common research activities which may be supported by national or international funding agencies or industrial consortiums

- synergies in physical establishment of learning factories, and

- leadership through anticipating new technologies and integration in these learning factories.

Driven by a strong interdisciplinary and trusted community, we will add unique value to tomorrow's manufacturing. Lets shape it together!

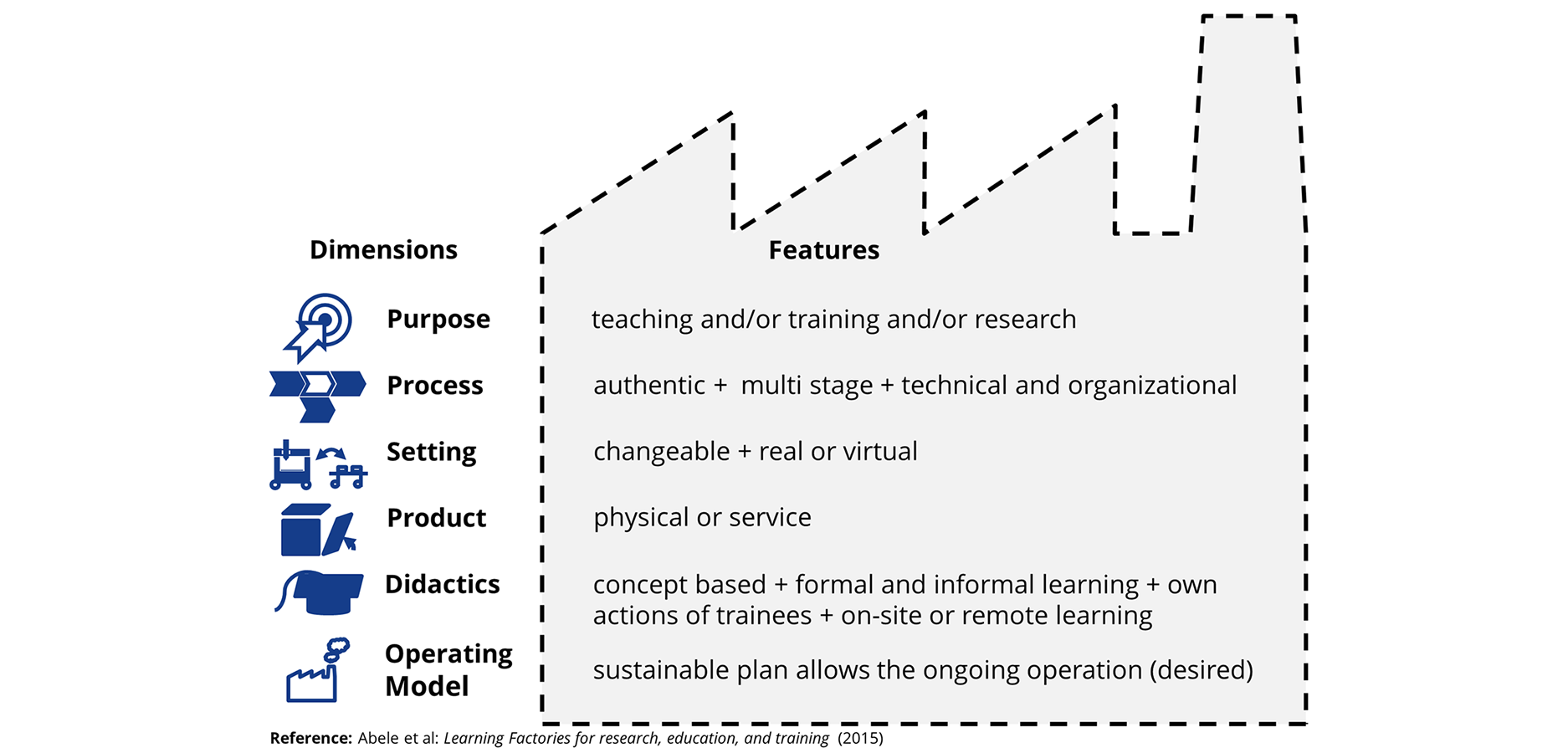

Definition of “learning factory”