EMEA - Europe, Middle East and Africa

- Fazel Ansari, Austria

- Friedrich Bleicher, Austria

- George Chryssolouris, Greece

- Peter Plapper †, Luxembourg

- Nikola Gjeldum, Croatia

- Thomas Gries, Germany

- Norbert Gronau, Germany

- Christoph Herrmann, Germany

- Vera Hummel, Germany

- Bernd Kuhlenkötter, Germany

- Gisela Lanza, Germany

- Bengt Lindberg, Sweden

- Louis Louw, South Africa

- Dominik Matt, Italy

- Laszlo Monostori, Hungary

- Joachim Metternich, Germany

- Christian Ramsauer, Austria

- Željko Stojkić, Bosnia & Herzegovina

- Sebastian Thiede, The Netherlands

- Sergio Terzi, Italy

- Valeriy Vyatkin, Finland

- Marc Wegmann, Germany

Prof. Fazel Ansari

Vienna University of Technology, Institute of Management Sciences (IMW), Austria

Fraunhofer Austria

Pilot Factory Industrie 4.0

Topics for Research and Training at Pilot Factory Industrie 4.0

- AI-based Production and Maintenance Planning: Artificial intelligence to increase productivity; IIoT solutions for maintenance; innovative service concepts e.g. chaptbots in maintenance

- Cyber-physical assembly and logistics systems: Assisting human workers instead of replacing them; cyber-physical assembly and logistic systems to master production challenges of the future

- Human-centered design of production systems: Design of optimized work-processes for human; realtime ergonomic evaluation of workplaces

- Work-based Learning: Human-machine reciprocal learning; focus on professional training with e.g. digital learning assistance systems

- Human-robot-collaboration: Collaboration between human and robot in several use cases, e.g. assembly process of 3D printing panels

- Digital assistance systems: Planning, implementation and integration of digital assistance systems; step-by-step worker guidance with XR

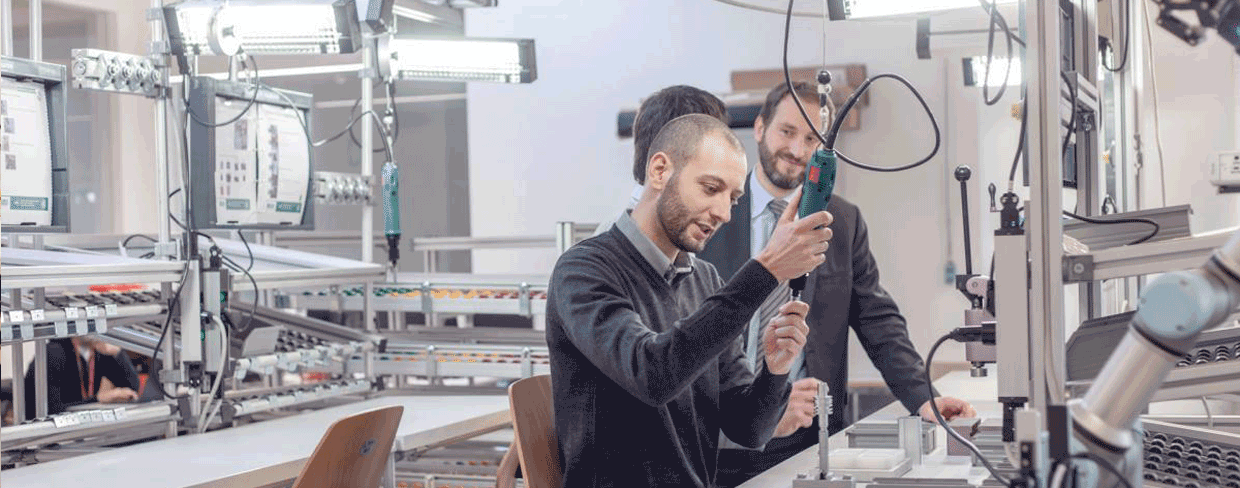

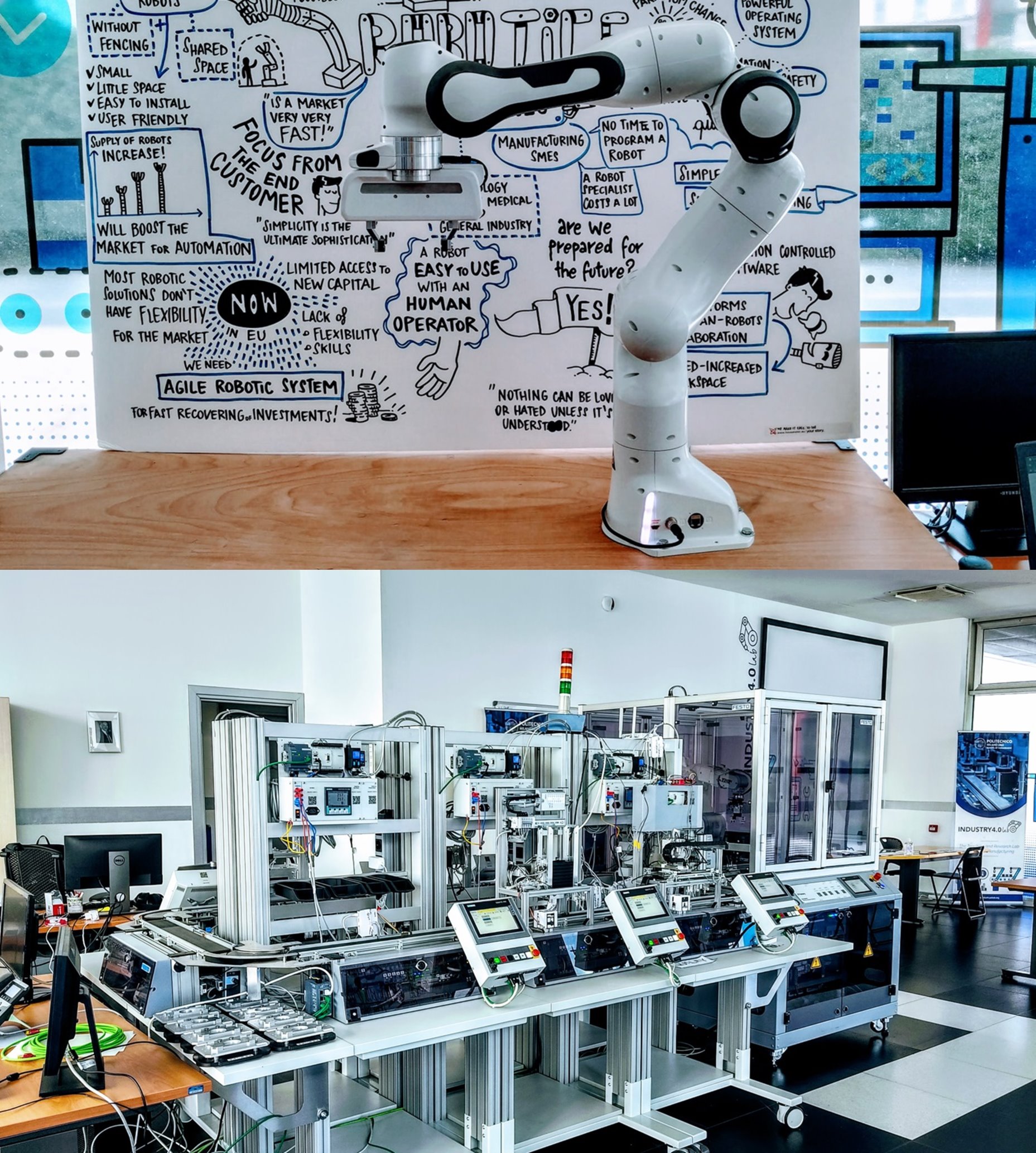

Impression of Pilot Factory Industrie 4.0

Contact

Prof. Friedrich Bleicher

Vienna University of Technology, Institute for Production Engineering (IFT), Austria

Pilot Factory Industrie 4.0

Topics for Research and Training at Pilot Factory Industrie 4.0

- Development and use-case-related implementation of methods and concepts for process pvent management in assembly

- Planning and evaluation of Digital and Visual Assistance Systems

- Planning and evaluation of Collaborative Human Robotic Systems

- Integrated safety and security concept for Collaborative Human Robotic Systems in cooperation with TÜV Austria

- MMAssist II: Development of modular and reusable digital and technical assistance systems in production, assembly and logistics

- Research collaboration on Smart Data Analytics for

- Prescriptive amd Predictive Maintenance

- Production Planning and Controlling

- Complex Event Processing

- Intralogistics

- Smart automation of industrial grade manufacturing cells

- Cloud-based automation for atomic machine functions

- Simulation and virtualization of manufacturing cells

- Knowledge- and function-based modeling in OPC UA

- Safety concepts for flexible manufacturing systems with AGV pallet handling

- MES layer integration for automated manufacturing

Impression of Pilot Factory Industrie 4.0

Topics for Research and Training at LMS Learning Factory

- Manufacturing Processes Modelling and Energy Efficiency

- Robots, Automation and Virtual Reality in Manufacturing

- Manufacturing Systems

Impressions of LMS Learning Factory

Contact

Topics for Research and Training at Operational Excellence Laboratory

-

Research focus

- Lean Manufacturing and beyond (Industry 4.0)

- Value Stream Mapping

- Process Optimization

- Augmented Reality and Digital Manuals

- Quality Management

- Increasing productivity and reducing lead time

- Production Planning and ControlInformation systems in learning factory

-

Topics for training

- Lean Manufacturing

- Industry 4.0

- Paper less assembly instructions

Impression of Operational Excellence Laboratory

Contact

Prof. Nikola Gjeldum

University of Split

Lean Learning Factory

Topics for research and training

-

Research Topics

- Design of Product Configurator

- Design and implementation of integrated application for kaizen and troubleshooting

- Model of Croatian Innovative Smart Enterprise

- ERP in Industry 4.0

- Using Cyber-Physical System and Virtual Reality for improvement of Factory Layout

- Management of Cyber-Physical Production Networks through Virtual Enterprise Information System

- Integrating Digital Factory, Lean Management and Industry 4.0 into the Learning Factory

- Digital Learning Factory

- Lifelong Learning in Learning Factory

- Concept of Information System Implementation (CRM AND ERP) within Industry 4.0

- Managing Innovative Production Network of Smart Factories

- Lean Learning Factory @ fesb: Information System Development in I4.0

-

Training Topics

- Lean management principles

- Lean management tools (VSM, kaizen, just-in-time, heijunka, jidoka, poka-yoke, 5S, PDCA, Six Sigma, TQM, Kata, Hoshin Kanri etc.)

- Logistic

- Plan Layout, Digital Factory

- Project Management

- Design for Assembly

- Assembly in Industry 4.0

- Additive Manufacturing (3D Scanning, 3D Printing)

Impressions

Contact

Topics for Research and Training at DCC Aachen

- Industry 4.0

- Condition monitoring

- Sensor technology

- Automation

- Consulting for decision making

- Support for implementation projects

Impression of DCC Aachen

Topics for Research and Training at CIP 4.0

Topics for research:

- Learning and teaching in the digital age

- Competence development in (hybrid) simulation environments

- Augmented and Virtual Reality enhanced learning

- Cyber-Physical Systems

- IoT, IIoT, Digital Twin

- IT-Security in the factory

- Innovative human-machine interaction

- Smart Factory

- Basics of Industry 4.0 principles

- Working with mobile devices (e.g., maintenance and production planning)

- Process optimization

- Augmented and Virtual Reality enhanced work processes

- IT-Security in the factory

Impression of Learning Factory for CIP 4.0

Topics for Research and Training at Die Lernfabrik

- Energy and resource efficiency in production

- Industry 4.0

- Urban factories

Impression of Die Lernfabrik

Topics for Research and Training at Werk150

-

System “Factory 4.0”

- Design of hybrid work systems: Human-robot-collaboration in production and intralogistics

- autonomously controlled, changeable intralogistics systems

- Digital Twin

- Digitally integrated product and process engineering & manufacturing

- Application of 5G technologies

- Smart products & digital business models

Impressions of Werk150

Topics for Research and Training at LPS Learning Factory

- Lean Management

- Workers’ participation

- Industrie 4.0 - assistance systems

- Lean meets Industrie 4.0

- Human-robot-collaboration in manual assembly lines

- Digital Twin and digital Shadow in production systems

- Artificial Intelligence (AI)/ Machine Learning (ML) methods for production processes (e.g. quality control, machine data-based quality prediction and human activity recognition)

- Human Centred Design of Artificial Intelligence in the HumAIne Competence Centre (https://humaine.info/ )

- MES application

- VR applications in Lean/Six Sigma seminars (https://www.lps.ruhr-uni-bochum.de/forschung/projekte/willen)

- Application of 5G Technologies in the competence centre 5Guarantee (https://5g.nrw/best-practice/5guarantee/)

- Future Hub for companies in the „Ruhrgebiet“ (http://www.sfs.tu-dortmund.de/cms/de/Aktuelles/201222_ChangeRuhr_Zukunfts-Hub_Ruhrgebiet/index.html)

- Support of producing SMEs in rural areas as a Mittelstand-Digital Centre Site in Bochum (https://digitalzentrum-lr.de/)

Impression of LPS Learning Factory

Contact

Topics for Research and Training at Learning Factory Global Production

- Site Selection

- Lean and Industry 4.0

- Data Mining for Quality Control

- Sourcing

- Fluid Automation

- Production Network Planning

- Collaboration and transparency in global production networks

Impression of Learning Factory Global Production

Contact

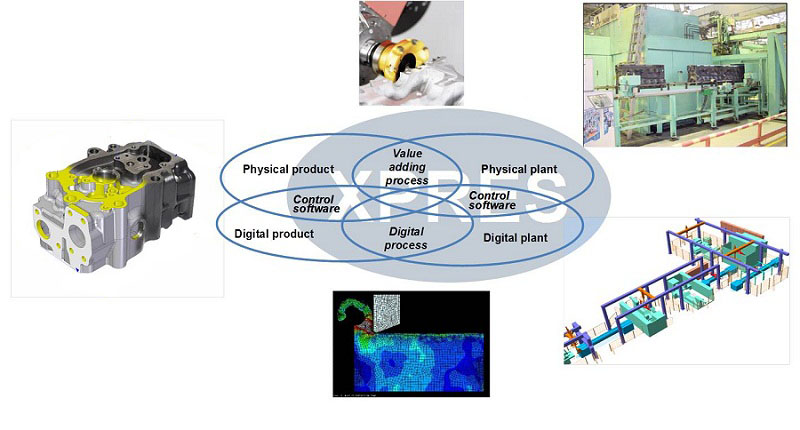

Topics for Research and Training at XPRES real lab

The ‘XPRES real lab’ provides new flexible/adaptive manufacturing lab facilities. This lab will allow manufacturing equipment to be installed for projects with a limited duration.

Impression of XPRES real lab

Contact

Topics for Research and Training at Stellenbosch Learning Factory

Research Topics

- The Application of Production-related Information Technology Architecture to Improve on Visual Management Systems within the Manufacturing Industry

- A framework for implementing Industrie 4.0

- Evaluating the benefit of an Internet-of-Things system to enhance data exchange and visibility to assist quality controlled logistics decisions.

Training Topics

- Lean Operations: Value stream mapping, Assembly line balancing

- Ergonomics: Time studies and Ergonomic Jig Design

- Shop-Floor-Management

Impression of Stellenbosch Learning Factory

Contact

Topics for Research and Training at Smart Mini Factory

- Automation and Robotics

- Human Machine Collaboration

- Lean and Flexible Assembly

- Intelligent and Sustainable Production

- Digital Production Management

- Worker Assistance Systems

- VR and AR in Production and Construction

- Construction 4.0 and BIM

Impression of Smart Mini Factory

Contact

Prof. Laszlo Monostori

Hungarian Academy of Sciences, Hungary

Centre of Excellence in Production Informatics and Control

Topics for Research and Training at Centre of Excellence in Production Informatics and Control

- Collaborative and advance robotic assembly

Impression of Centre of Excellence in Production Informatics and Control

Prof. Joachim Metternich

Technische Universität Darmstadt, Germany

Process Learning Factory - Center for industrial Productivity (CiP)

FlowFactory

Topics for Research and Training at Process Learning Factory (CiP)

Topics for Research at CiP:

- Learning factories and competence development for production

- Shopfloor management and problem solving

- Data Science and Artificial Intelligence in Production

- Value stream management

Excerpt from current research projects at CiP:- DIONE-X: Secure and powerful data rooms for the machining value network Digital shopfloor management

- Flex4res: Data spaces for flexible production lines and supply chains for resilient production

- Digital Centre Darmstadt

- CiP curriculum consists of 17 teaching modules addressing topics like:

- Basics of Lean Production

- Value stream analysis and design

- Shopfloor Management

- Data science and artificial intelligence

- Energy efficiency

Impression of the Process Learning Factory

Topics for Research and Training at FlowFactory

Topics for Research at FlowFactory:

- Human-centred assistance systems in cyber-physical production environments

- Data-driven process optimisation and business model innovation

- Traceability to support digital twins

- Learning factories and competence development for production

- Shopfloor management and problem solving

- Data Science and Artificial Intelligence in Production

- Value stream management

The FlowFactory opened its doors in September 2023 and a training program is currently under development. Trainings will conduct topics like resilient production, circular economy in production and AI for production.

Impression of the FlowFactory

Topics for Research and Training at LEAD Factory

- Holistic concept of agility to proactively prepare for uncertainties

- Age appropriate worker assistance and workplace design

- Teaching concepts based on skill requirement of the workforce of the future

- Lean Management: Lean principles, logistics principles, 5S, value stream mapping, line balancing, shop floor management, etc.

- Energy Efficiency: Energy measurements, methods to decline energy consumption

- Agility: Uncertainty and its impact on manufacturing, monitoring to early detect and fast react, governance & organization, strategic alignment, operational agility levers

- Digitalization: Digitalization technologies, implementation of digitalization projects and strategy, digital business models

Impression of LEAD Factory

Contact

Topics for Research and Training at FSRE Learning Factory

Research focus

-

Information systems in learning factory

-

Intralogistics

-

Factory design layout

-

Product development

-

Additive manufacturing

- Energy efficiency in manufacturing

Topics for training

-

Lean tools and lean engineering

-

Shopfloor management

-

Rapid prototyping

-

Information systems

- Product design and development

Impression of FSRE Learning Factory

Contact

Prof. Sebastian Thiede

University of Twente, The Netherlands

Topics for Research and Training

- Smart manufacturing solutions based on Cyber Physical Production System (CPPS) framework (e.g. data acquisition strategies, machine learning and factory simulation, decision support and control)

- Methods for factory planning and operation (e.g. layout planning, planning and control, quality management, lean management)

- Innovative manufacturing systems/factory concepts (e.g. flexible production systems, scale up scenarios)

- Sustainable manufacturing (e.g. energy and resource efficiency)

- Human factors in manufacturing systems (e.g. occupational health and safety, ergonomics, workplace design)

Impression

Contact

Topics for Research and Training

- Digital Manufacturing

- Sustainable Manufacturing

- Operations Management

Impression

Contact

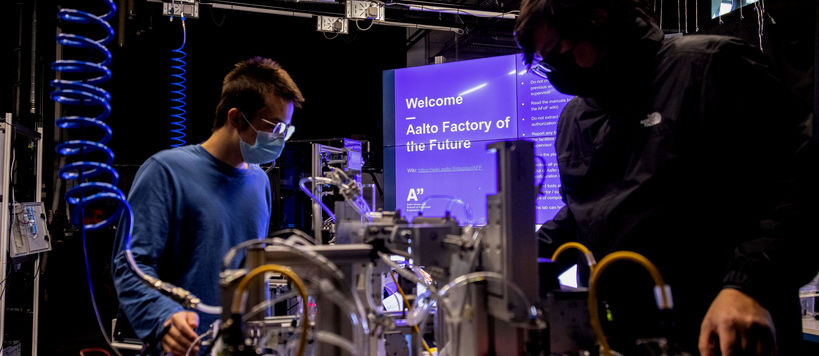

Topics for Research and Training at Aalto Factory of the Future

- Methods for decentralized / distributed automation of industrial systems, including the impact of wireless communications such as 5G and beyond

- Enablers of Flexible production systems

- Artificial intelligence for industrial manufacturing / environments

- Digital twins, simulation models of industrial systems

- Safety and security of current and future industrial systems

Impression of Aalto Factory of the Future

Contact

Marc Wegmann

Interim contact person of TU Munich on behalf of Prof. Zäh

Technical University of Munich, Germany

iwb Smart Production Lab (SPL)

Topics for Research and Training at iwb Smart Production Lab (SPL)

- Innovative Learning Environment: Experience a place where theory meets practice

- Lean Management: Enhance production efficiency and reduce waste to achieve peak performance

- Robotics: Increase productivity and optimize workflows through automation.

Circular Economy: Promote sustainable production by efficiently using resources and reducing waste - Digitalization: Prepare for the future by recognizing potential, leveraging quick wins, and revolutionizing processes

Impression of iwb Smart Production Lab (SPL)